What are the requirements for the control handle and foot switch of an acrylic diamond polishing machine?

Foshan Zhuohong Electromechanical Equipment Co., Ltd. specializes in the production and sale of acrylic diamond polishing machines.

What are the requirements for the control handle and foot switch of an acrylic diamond polishing machine? Let Zhuohong Electromechanical tell you.

(1) Important handles should have reliable positioning and locking devices. Coaxial handles should have a clear difference in length.

(2) The handwheel can be disengaged from the rotating shaft during operation to prevent injury to personnel from the rotating shaft.

(3) The foot switch should have a protective cover or be recessed into the bed to prevent dropped parts from falling onto the switch and starting the machinery, causing injury.

(4) The work site of the machinery should have a good environment, i.e., appropriate illumination, moderate humidity and temperature, low noise and vibration, and neatly arranged parts and tools. This will help operators to work in a relaxed and focused manner.

(5) Each piece of machinery should have safety operating procedures and inspection, lubrication, and maintenance systems established based on its performance and operating sequence for operators to follow.

Foshan Zhuohong Electromechanical Equipment Co., Ltd. has a modern standard factory, advanced equipment, exquisite technology, and first-class management. We are wholeheartedly committed to serving our customers, and customer satisfaction is our goal. All employees of the acrylic diamond polishing machine manufacturer adhere to the business philosophy of "pursuing excellence, continuous innovation, sincere cooperation, and mutual benefit," and have received high praise from our new and old customers.

Related News

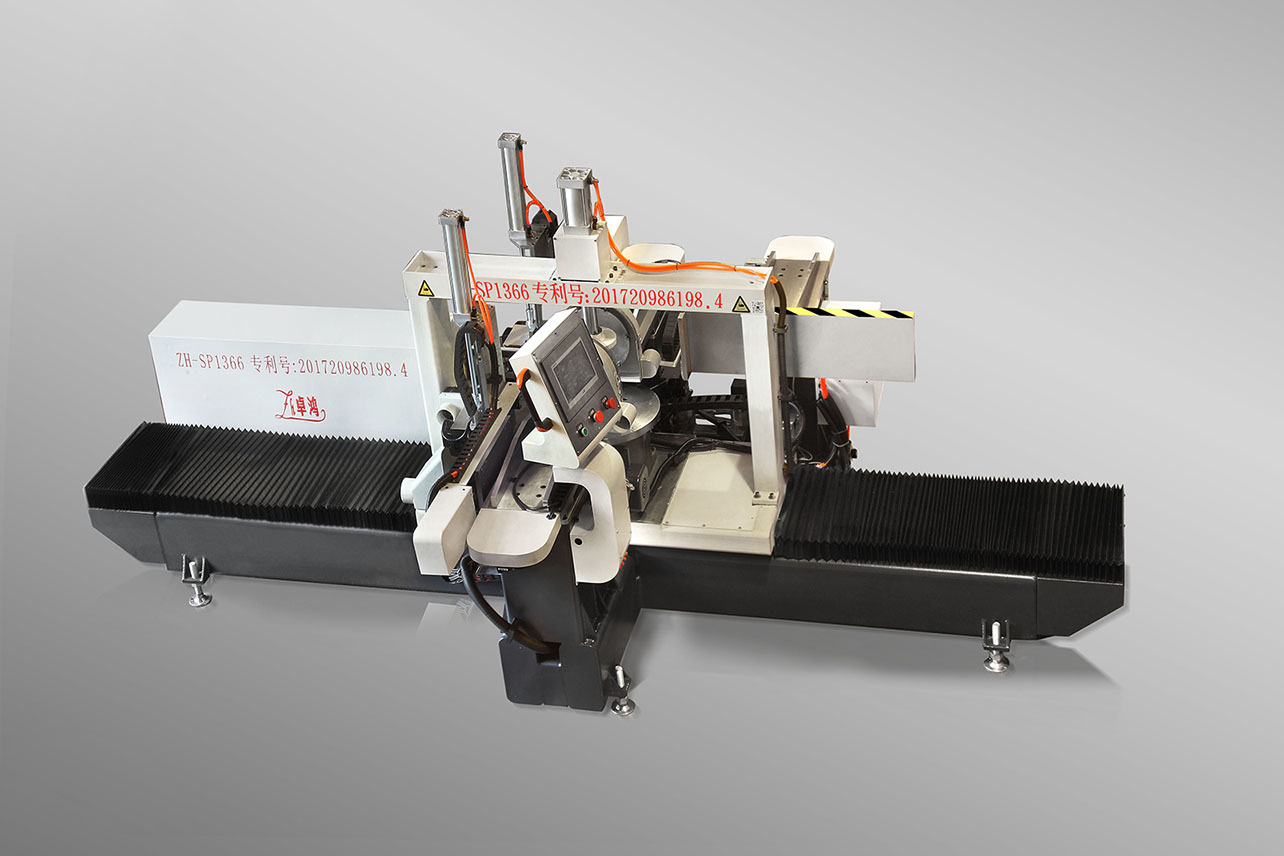

Features of electronic panel saws

By adding automatic feeding and positioning devices to the reciprocating saw, an electronic panel saw is created. Electronic panel saws use CNC program control. Workers input the required dimensions and quantity of materials on a touch screen or PC, start the machine, and the machine automatically feeds, positions, and cuts the materials. It features high cutting accuracy and efficiency, reduces worker workload, and is widely used in furniture factories, packaging factories, hardware factories, and appliance factories (lighting) for efficient processing of panels. Below, we introduce the features of electronic panel saws. Features of electronic panel saw cutting: 1, Automatic saw carriage