Cutting light guide plates requires a certain level of physical fitness from employees.

Foshan Zhuohong Electromechanical Equipment Co., Ltd. specializes in light guide plate cutting projects.

Light guide plates are essential components in the backlight assembly stage of LCD TV modules. Production demand is high, requiring sufficient inventory. In terms of production processes, raw materials need to be manually transported from the hydraulic forklift to the cutting machine. The input of machine model specifications during production, light guide plate cutting, positioning, and milling processes require high precision, with dimensional accuracy down to the millimeter, often requiring manual measurement with a ruler.

This not only requires certain physical fitness from employees but also demands meticulous attention to detail and proficiency in operating and adjusting production machinery. According to relevant personnel from Zhuohong Electromechanical, it takes a new employee months of hands-on experience and training to master the skills, precision, and output control of light guide plate production, ensuring production efficiency.

Light guide plates are made using optical-grade acrylic sheets with high-tech materials that have high reflectivity and do not absorb light. A light guide pattern is printed on the surface of the acrylic sheet using a technical method. After the light guide plate is produced, it needs to be cut according to the required specifications. Currently, the main method is manual cutting of the light guide plate using a blade by processing personnel.

Foshan Zhuohong Electromechanical Equipment Co., Ltd. possesses strong light guide plate cutting technology and has accumulated rich experience. We provide customers with various solutions. While continuously improving product quality, to meet the needs of fierce market competition, we constantly improve production equipment and methods, increase production efficiency, significantly shorten product delivery times and new product development cycles, and provide guarantees for the long-term development needs of our customers.

Related News

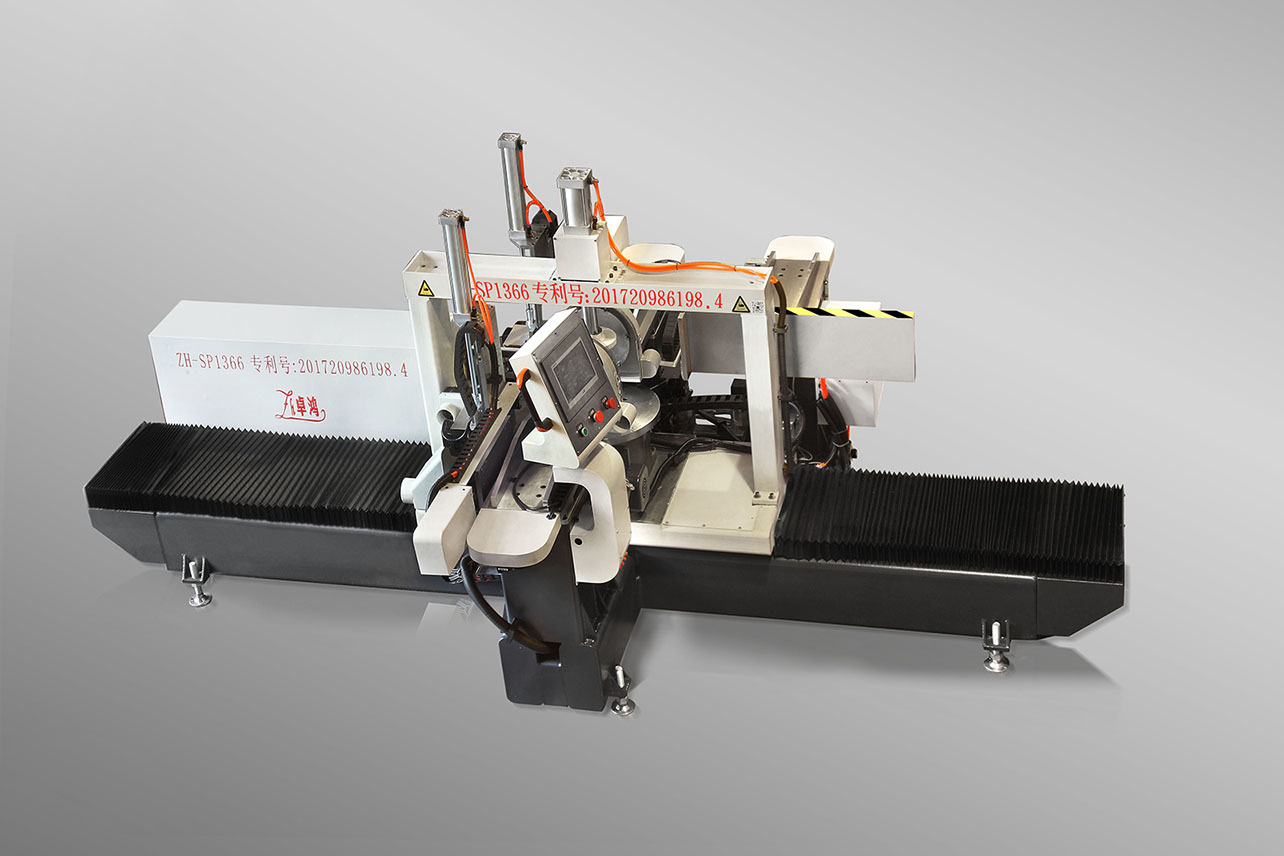

Features of electronic panel saws

By adding automatic feeding and positioning devices to the reciprocating saw, an electronic panel saw is created. Electronic panel saws use CNC program control. Workers input the required dimensions and quantity of materials on a touch screen or PC, start the machine, and the machine automatically feeds, positions, and cuts the materials. It features high cutting accuracy and efficiency, reduces worker workload, and is widely used in furniture factories, packaging factories, hardware factories, and appliance factories (lighting) for efficient processing of panels. Below, we introduce the features of electronic panel saws. Features of electronic panel saw cutting: 1, Automatic saw carriage