Acrylic diamond polishing machine manufacturers tell you how diamonds are polished

Foshan Zhuohong Electromechanical Equipment Co., Ltd. specializes in the production and sale of acrylic diamond polishing machines.

Today, let's talk about how diamonds are polished using acrylic diamond polishing machines.

Diamonds are polished by placing diamond powder on a high-speed rotating lead lap using a diamond polishing machine.

The polish and symmetry of a diamond are two of the most important aspects of the cutting process. The polish grade describes the smoothness of the diamond's surface, while the symmetry grade refers to the arrangement of the diamond's facets. Poor polishing quality directly affects the diamond's optical effect. On an uneven surface, light undergoes diffuse reflection, causing the surface of the diamond facet to appear dull and colorless, emitting a cloudy or dim light. Deviations in symmetry cause incident light or the diamond's own light to deviate from its designed path. The descriptions of diamond polish and facet symmetry grades are clearly and comprehensively listed in each diamond grading report. For diamond polish and symmetry grades, GIA and HRD use ID (standard), EX (excellent), VG (very good), and G (good), while the China National Inspection uses EX (excellent), VG (very good), and G (good). Diamonds with polish and symmetry grades of F or P should be avoided, as the symmetry of such diamonds may greatly mislead the reflection and refraction of light, thus affecting the diamond's brilliance.

The measurement of a diamond's polish and symmetry is reasonable and used as a grading standard for cut, making it easy to understand how the diamond reflects light.

Foshan Zhuohong Electromechanical Equipment Co., Ltd. has a team of highly qualified R&D personnel, management personnel, and sales elites, with strong R&D, production, and sales capabilities. We not only provide customers with high-quality products and services such as acrylic diamond polishing machines, but also provide customized overall solutions for customers' specific applications.

Related News

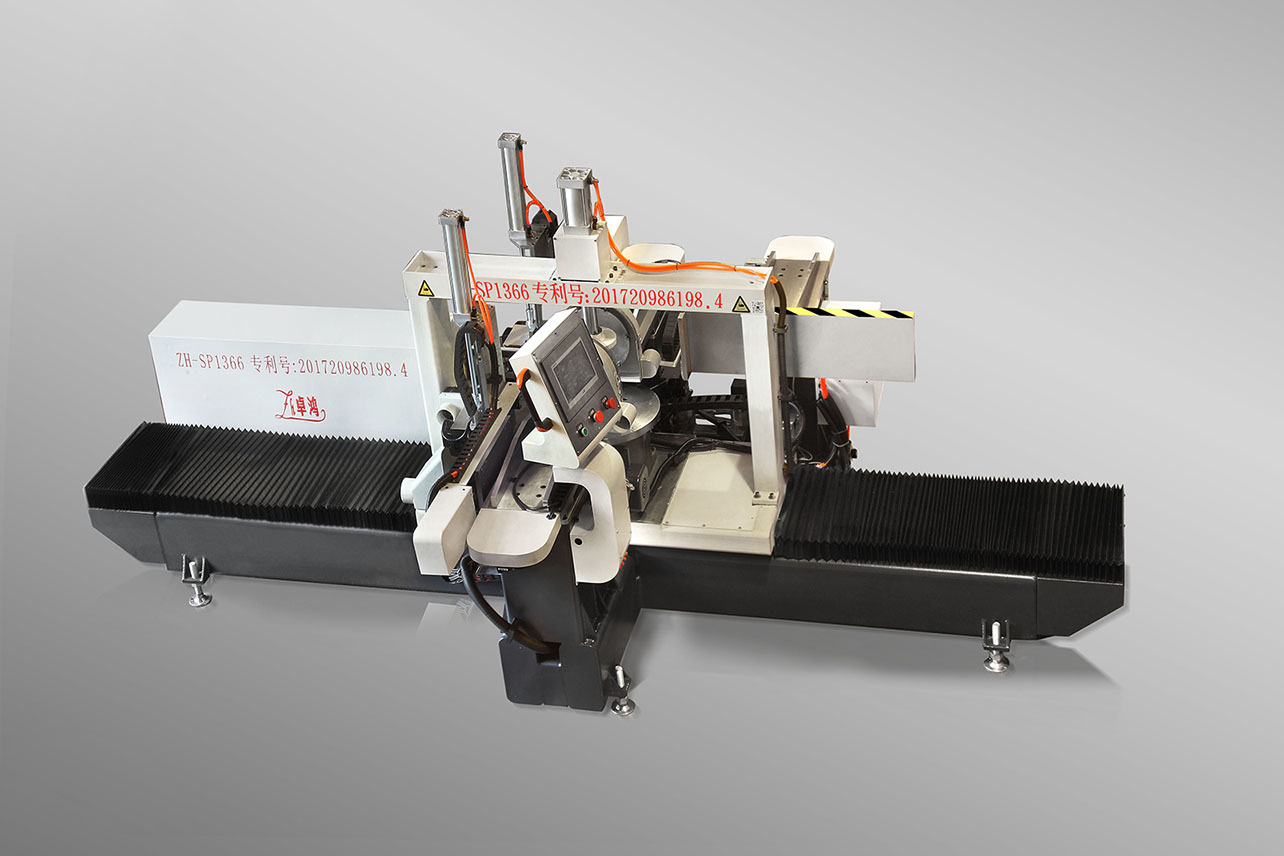

Features of electronic panel saws

By adding automatic feeding and positioning devices to the reciprocating saw, an electronic panel saw is created. Electronic panel saws use CNC program control. Workers input the required dimensions and quantity of materials on a touch screen or PC, start the machine, and the machine automatically feeds, positions, and cuts the materials. It features high cutting accuracy and efficiency, reduces worker workload, and is widely used in furniture factories, packaging factories, hardware factories, and appliance factories (lighting) for efficient processing of panels. Below, we introduce the features of electronic panel saws. Features of electronic panel saw cutting: 1, Automatic saw carriage