Backlight cutting manufacturers introduce the characteristics of light guide plates

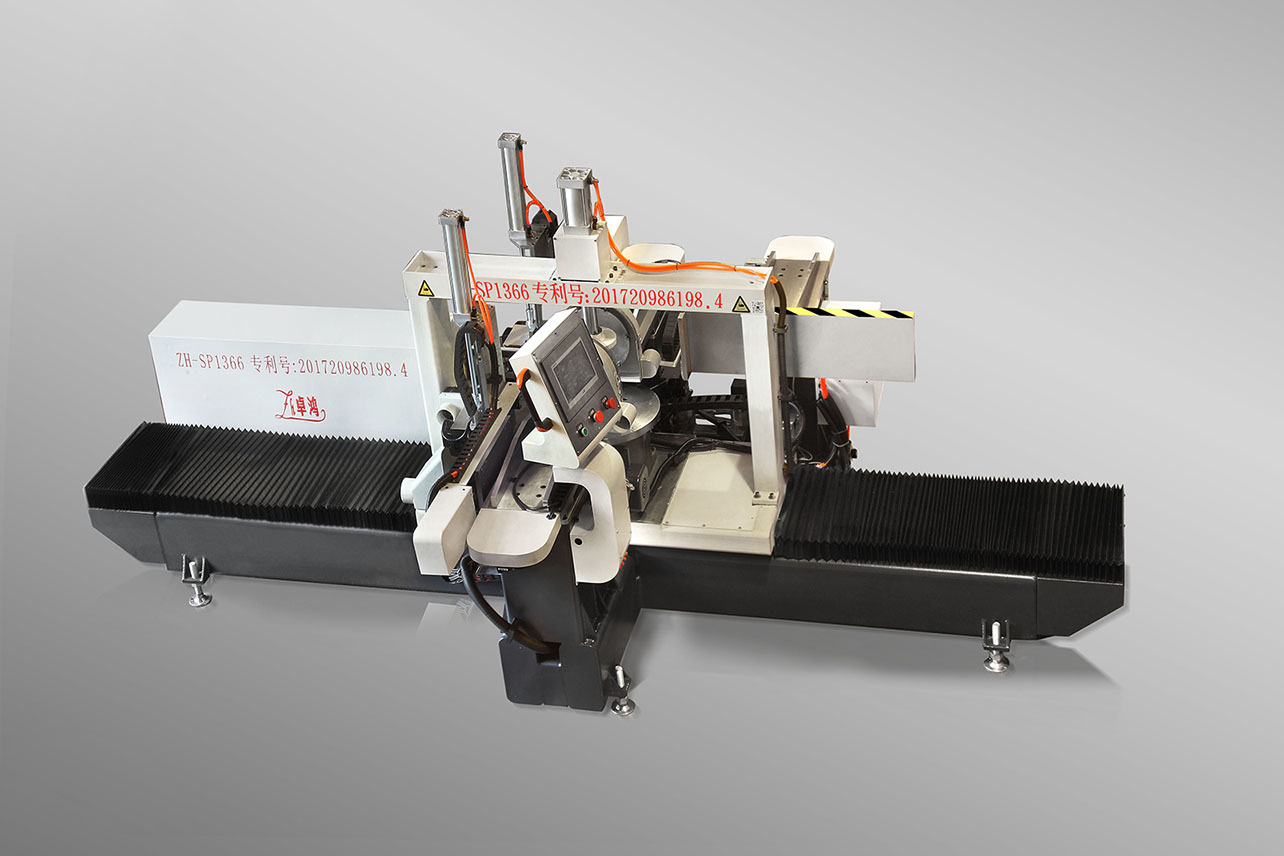

Foshan Zhuohong Electromechanical Equipment Co., Ltd. specializes in the production and sale of equipment for light guide plate cutting and other products.

According to light guide plate cutting manufacturers, light guide plates utilize optical-grade acrylic/PC materials. High-reflectivity, non-light-absorbing high-tech materials are then used to print light guide dots onto the bottom surface of the optical-grade acrylic plate using UV screen printing technology. The optical-grade acrylic plate absorbs light emitted from the lamp and retains it on the surface. When light hits the light guide dots, the reflected light diffuses in various directions, breaking the reflection conditions and emitting from the front of the light guide plate. Through light guide dots of various densities and sizes, the light guide plate can emit light evenly. The reflector's purpose is to reflect the light exposed on the bottom surface back into the light guide plate to improve light efficiency; under the same area and luminous brightness, the luminous efficiency is high, and the power consumption is low. Single-sided micro-structured array light guide plates generally use extrusion molding.

Below, the light guide plate cutting manufacturer will briefly introduce the characteristics of the light guide plate.

1. It can be arbitrarily cut to the required size, or it can be spliced together. The process is simple and easy to manufacture;

2. High light conversion rate (30% higher than traditional plates), uniform light, long lifespan (more than 8 years of normal indoor use), safe and environmentally friendly, durable and reliable for both indoor and outdoor use;

3. Under the same area and luminous brightness, the luminous efficiency is high, and the power consumption is low;

4. It can be made into various shapes, such as circles, ovals, arcs, and triangles;

5. Under the same brightness, thinner products can be used, saving costs;

6. Any light source can be used, converting line light sources into surface light sources. Light sources include LED, CCFL (cold cathode fluorescent lamp), and fluorescent tubes.

Foshan Zhuohong Electromechanical Equipment Co., Ltd. is committed to high quality and high standards, striving for excellence to meet customer needs. All staff at the light guide plate cutting manufacturer warmly welcome customers to discuss business with us, providing external processing and customized services to meet various requirements. We work together to expand the market and establish mutually beneficial cooperative relationships. We strive to be your most trusted business partner.

Related News

Features of electronic panel saws

By adding automatic feeding and positioning devices to the reciprocating saw, an electronic panel saw is created. Electronic panel saws use CNC program control. Workers input the required dimensions and quantity of materials on a touch screen or PC, start the machine, and the machine automatically feeds, positions, and cuts the materials. It features high cutting accuracy and efficiency, reduces worker workload, and is widely used in furniture factories, packaging factories, hardware factories, and appliance factories (lighting) for efficient processing of panels. Below, we introduce the features of electronic panel saws. Features of electronic panel saw cutting: 1, Automatic saw carriage