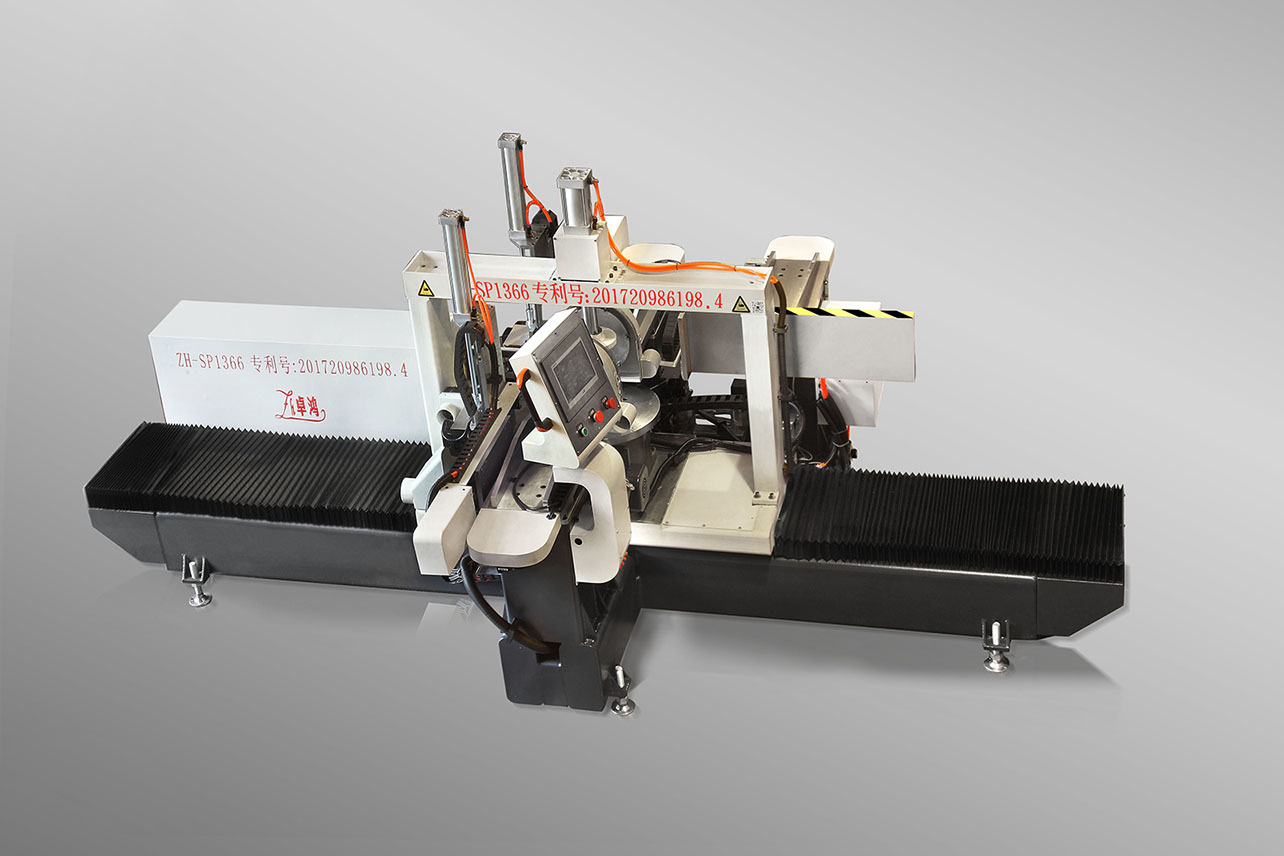

The best manufacturer of light guide plate polishing machines in Hangzhou

Foshan Zhuohong Electromechanical Equipment Co., Ltd. is dedicated to the research, development, production, and sales of light guide plate polishing machines and other products.

Applicable industries for light guide plate polishing machines:

Mobile phone industry (including Apple phones and tablets, Xiaomi, Huawei, etc.), electronics industry, LED industry, precision hardware industry, communication equipment industry, plastic mold industry, optical glass industry, aerospace industry, ceramics industry, etc.

Applicable materials for light guide plate polishing machines:

Products made of stainless steel, tungsten steel, aluminum, and alloy metals; products made of optical glass, silicon wafers, light guide plates, acrylic, sapphire substrates, sapphire epitaxial wafers, plastics, and other non-metallic superhard materials.

Uses of light guide plate polishing machines:

Widely used in light guide plate mirror polishing, mold light guide plate processing, die mirror polishing, LED sapphire substrate mirror polishing, flat panel light guide plate mirror polishing, mobile phone light guide plate mirror polishing, mobile phone panel mirror polishing, etc.

Working principle of light guide plate polishing machine:

1. This grinding machine is a precision grinding equipment. The product to be ground is placed on the grinding disc. The grinding disc rotates counterclockwise, and the workpiece rotates by itself. The pressure is applied to the workpiece by gravity. The workpiece and the grinding disc rotate and rub relatively to achieve the grinding purpose.

2. The disc repair machine uses hydraulic suspension guide rails and a diamond dressing knife to precisely adjust the grinding disc, so that the grinding disc obtains precise flatness.

With rich production management experience, quality management experience, and a skilled technical team, our factory provides high-quality light guide plate polishing machines and other products and professional services to our customers.

We sincerely welcome new and old customers to inquire about business and provide guidance.

Foshan Zhuohong Electromechanical Equipment Co., Ltd.

Contact person: Mr. Zheng (13923212848)

Tel: 0757-81180742

Fax: 0757-81180743

Email: zhuohong2011@126.com

Nationwide toll-free service hotline: 400-670-5068

Address: No. 65, Xiebian Hengjiao Industrial Zone, Nanhai District, Foshan City

Related News

Features of electronic panel saws

By adding automatic feeding and positioning devices to the reciprocating saw, an electronic panel saw is created. Electronic panel saws use CNC program control. Workers input the required dimensions and quantity of materials on a touch screen or PC, start the machine, and the machine automatically feeds, positions, and cuts the materials. It features high cutting accuracy and efficiency, reduces worker workload, and is widely used in furniture factories, packaging factories, hardware factories, and appliance factories (lighting) for efficient processing of panels. Below, we introduce the features of electronic panel saws. Features of electronic panel saw cutting: 1, Automatic saw carriage