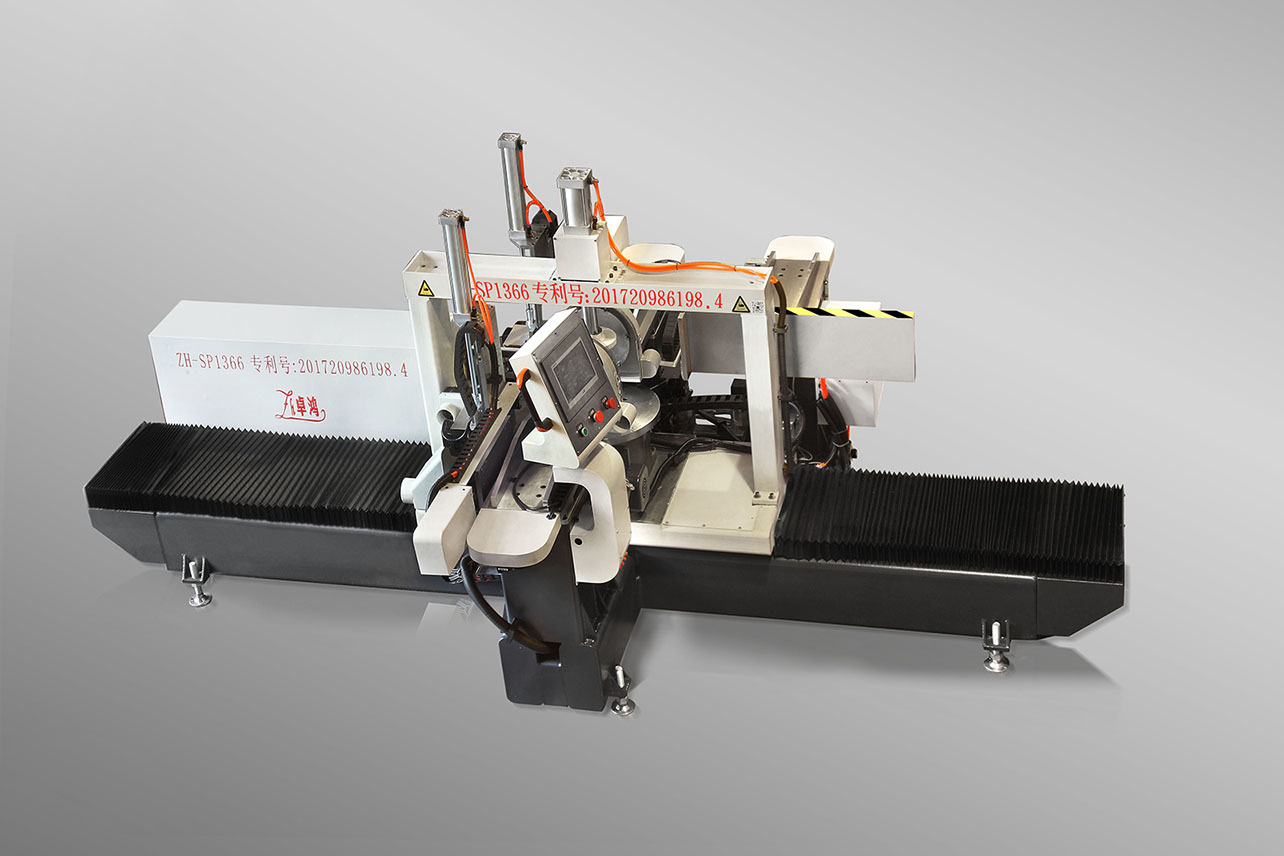

Suzhou High-Quality Acrylic Diamond Polishing Machine Manufacturer

Foshan Zhuohong Electromechanical Equipment Co., Ltd. is dedicated to the design, research and development, production, and sales of acrylic diamond polishing machines.

The basic principle of an acrylic diamond polishing machine is a physical process where fine and coarse blades on the cutting disc perform high-speed cutting of the material surface, layer by layer, in a circular motion.

The materials polished by the acrylic diamond polishing machine have a crystal-clear surface, meeting customer quality requirements while significantly improving work efficiency, saving labor and time costs, and enhancing the company's competitive advantage.

To meet the production needs of large enterprise orders, avoid production delays, ensure timely delivery, and guarantee the processing quality of acrylic products, the acrylic diamond polishing machine solves a series of problems faced by enterprises.

At the same time, the acrylic diamond polishing machine is also a hardware guarantee for showcasing the company's strength. Nowadays, some customers inspect the factory's production capacity before placing orders, and equipment is one of the most important indicators.

Our company adheres to the business philosophy of technological innovation, focusing on quality and offering high-quality products at reasonable prices. We have a 24-hour service hotline to ensure timely customer feedback, earning the trust and support of our customers.

We sincerely look forward to your call for consultation, business discussions, and guidance.

Foshan Zhuohong Electromechanical Equipment Co., Ltd.

Contact Person: Mr. Zheng (13923212848)

Tel: 0757-81180742

Fax: 0757-81180743

Email: zhuohong2011@126.com

Toll-free service hotline: 400-670-5068

Address: No. 65, Xiebian Hengjiao Industrial Zone, Nanhai District, Foshan City

Related News

Features of electronic panel saws

By adding automatic feeding and positioning devices to the reciprocating saw, an electronic panel saw is created. Electronic panel saws use CNC program control. Workers input the required dimensions and quantity of materials on a touch screen or PC, start the machine, and the machine automatically feeds, positions, and cuts the materials. It features high cutting accuracy and efficiency, reduces worker workload, and is widely used in furniture factories, packaging factories, hardware factories, and appliance factories (lighting) for efficient processing of panels. Below, we introduce the features of electronic panel saws. Features of electronic panel saw cutting: 1, Automatic saw carriage