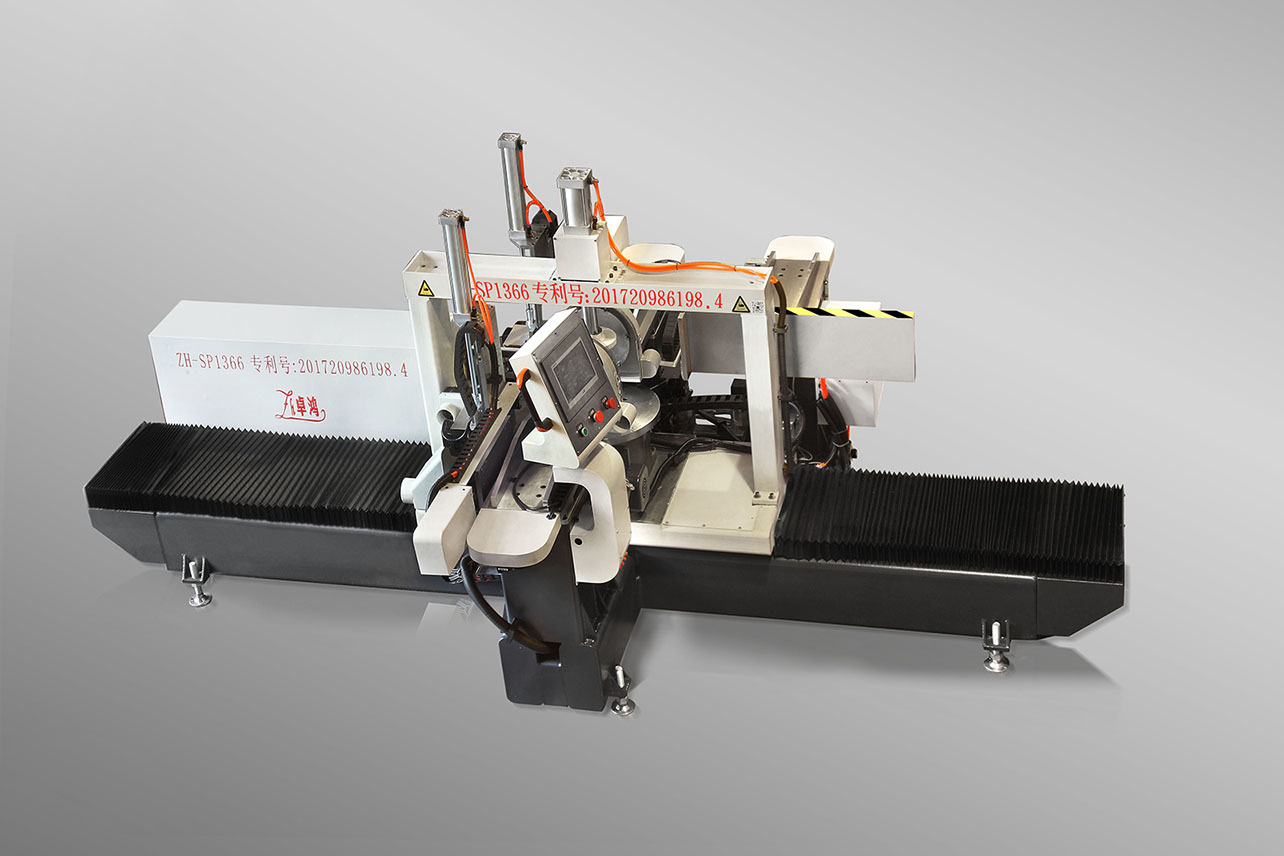

Beijing high-quality acrylic double polishing machine factory direct sales

Foshan Zhuohong Electromechanical Equipment Co., Ltd. is dedicated to the design, research and development, production, and sale of products such as acrylic double polishing machines.

Below, the professional manufacturer and seller of acrylic double polishing machines will introduce the acrylic polishing process of acrylic polishing machines.

Acrylic is polished because processing (cutting, milling, turning) requires a frosted surface. Since acrylic is mainly used for visualization, there is usually a step of polishing the visible surface (making it transparent).

There are various acrylic polishing processes, and the polishing method used depends on the geometry of the part:

1. Diamond edge polishing: Acrylic diamond polishing machines are suitable for all board edges, precision polishing of high-grade acrylic products and crystal products, with extremely high product quality and efficiency.

2. Cloth wheel polishing: Using a cloth wheel polishing machine can only remove fine lines and stains from plexiglass, improve surface finish, reduce haze, until a mirror-like shine is achieved.

3. Flame polishing: Suitable for polishing irregularly shaped products.

4. Manual polishing: Use sandpaper, or felt or degreased cotton balls dipped in polishing paste for polishing, suitable for large flat surface polishing.

5. Direct processing with a laser cutting machine results in a smooth surface.

Foshan Zhuohong Electromechanical Equipment Co., Ltd. boasts strong R&D technical capabilities and a powerful production and sales team for products such as acrylic double polishing machines.

The acrylic double polishing machines and other products we introduce to the market are of superior quality, reasonably priced, and come with comprehensive and thoughtful after-sales service, consistently earning high praise and favor from customers.

We warmly welcome friends from home and abroad to visit our factory for guidance, processing with provided drawings, and ordering with samples. We cordially invite domestic and international business partners to visit and discuss business!

Foshan Zhuohong Electromechanical Equipment Co., Ltd.

Contact Person: Mr. Zheng (13923212848)

Phone: 0757-81180742

Fax: 0757-81180743

Email: zhuohong2011@126.com

National Toll-Free Service Hotline: 400-670-5068

Address: No. 65, Xiebianhengjiao Industrial Zone, Nanhai District, Foshan City

Related News

Features of electronic panel saws

By adding automatic feeding and positioning devices to the reciprocating saw, an electronic panel saw is created. Electronic panel saws use CNC program control. Workers input the required dimensions and quantity of materials on a touch screen or PC, start the machine, and the machine automatically feeds, positions, and cuts the materials. It features high cutting accuracy and efficiency, reduces worker workload, and is widely used in furniture factories, packaging factories, hardware factories, and appliance factories (lighting) for efficient processing of panels. Below, we introduce the features of electronic panel saws. Features of electronic panel saw cutting: 1, Automatic saw carriage