How to properly use an acrylic polishing machine

How to use correctly Acrylic polishing machine

Relative to Acrylic polishing machine In our lives, there are many times when we need to use such products. However, when it comes to using an acrylic polishing machine, we don't know what precautions to take. So, what are the precautions for its use? Let's take a look below:

1. Pay attention to damage and scratches:

The surface hardness of acrylic resin is the same as that of aluminum. Although plastic is hard, care must be taken when using it. To protect the surface, protective paper is affixed to the acrylic resin. During use, to prevent scars and dust adhesion, I suggest you try to paste protective paper during use and peel it off at the end. In addition, during operation, due to hand protection, the surface of the board must also be protected. Please wear protective equipment, gloves, etc. When cleaning the dirt on the surface of the board, use a soft cloth dipped in water or neutral detergent.

2. Precautions for adhering dust: Pay attention to dust prevention

If you wipe the surface of the acrylic resin with a dry cloth, there will be friction and a tendency to become charged, easily adhering to the air, causing dust and scars. Please pay attention. It is recommended to gently wipe with a soft cloth containing anti-static agent or methanol containing anti-static agent.

3. Precautions for linear expansion:

Like many plastics, it has a linear expansion rate, and this must be considered when the temperature changes. We hope to maintain and handle it under constant conditions. If there is a temperature difference, for example, a temperature difference of 20 degrees Celsius, it will be approximately 1.4 mm per 1 m length.

4. Precautions for solvents:

Corrosion by paints and solvents can cause surface cracking. Therefore, do not store it in paint storage rooms, spray booths, and other places with solvent vapor. Please use it in a clean place.

5. Pay attention to temperature:

The operating temperature of the new light board is 80℃, and it will deform at high temperatures. Therefore, keep the temperature below 50 degrees.

Storage method

6. Precautions for storage method:

It can be used horizontally and vertically. Both methods have their advantages. Incorrect storage can lead to warping.

7. Precautions for humidity:

Humidity will also cause expansion. The response speed is not as fast as the temperature change, so pay attention when using it. If the water absorption of the board is uneven, its extension varies depending on the board, and sometimes warping occurs.

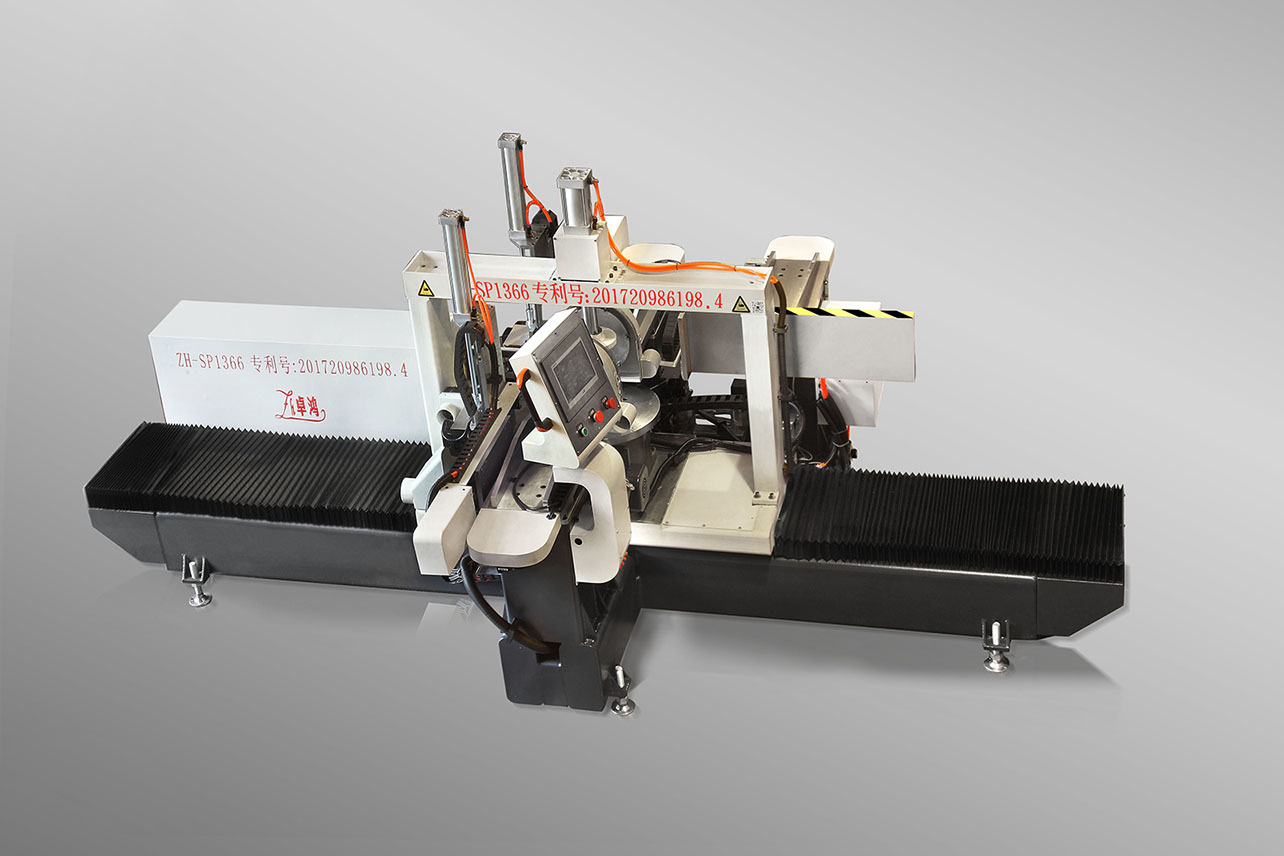

This article is about the precautions for using Acrylic polishing machine For more details, please call our company Foshan Zhuohong Electromechanical Equipment Co., Ltd. More professional personnel will answer your questions

Related News

Features of electronic panel saws

By adding automatic feeding and positioning devices to the reciprocating saw, an electronic panel saw is created. Electronic panel saws use CNC program control. Workers input the required dimensions and quantity of materials on a touch screen or PC, start the machine, and the machine automatically feeds, positions, and cuts the materials. It features high cutting accuracy and efficiency, reduces worker workload, and is widely used in furniture factories, packaging factories, hardware factories, and appliance factories (lighting) for efficient processing of panels. Below, we introduce the features of electronic panel saws. Features of electronic panel saw cutting: 1, Automatic saw carriage