What factors affect the cutting speed of an acrylic polishing machine?

Many customers using acrylic cutting machines to cut acrylic sheets hope for high cutting speeds; however, this is often not the case. The cutting speed of an acrylic laser cutting machine is significantly related to the material being cut.

1. The Relationship Between Acrylic Cutting Machine Cutting Speed and Material Properties

Acrylic laser cutting machines commonly process materials such as acrylic sheets, wood, PVC, and plastic. Sometimes, they may also cut metals like aluminum and steel. However, it's easy to see that the cutting speed for acrylic and plastic is much faster than for aluminum and steel. This is largely due to material properties. Metals like aluminum and steel are highly reflective, causing some laser reflection during cutting, reducing efficiency. Slower speeds are necessary for better results; therefore, the cutting speed of an acrylic laser cutting machine is greatly influenced by the material's properties.

2. The Relationship Between Acrylic Laser Cutting Machine Cutting Speed and Material Thickness

When laser cutting acrylic sheets, thinner sheets are generally easier and faster to cut than thicker ones. Therefore, the cutting speed is related to the material thickness.

3. The Relationship Between Acrylic Cutting Machine Cutting Speed and the Use of Auxiliary Gases

Auxiliary gases are often used when laser cutting difficult-to-cut metals. These gases aid combustion. Commonly used gases include oxygen and nitrogen. Using these gases can increase speed by three times compared to using compressed air. Therefore, the cutting speed is significantly affected by the use of auxiliary gases.

To learn more about acrylic polishing machines, diamond tool grinders, and acrylic diamond polishing machines, please visit the Foshan Zhuohong Electromechanical Equipment Co., Ltd. website: www.fszhjd.com

Related News

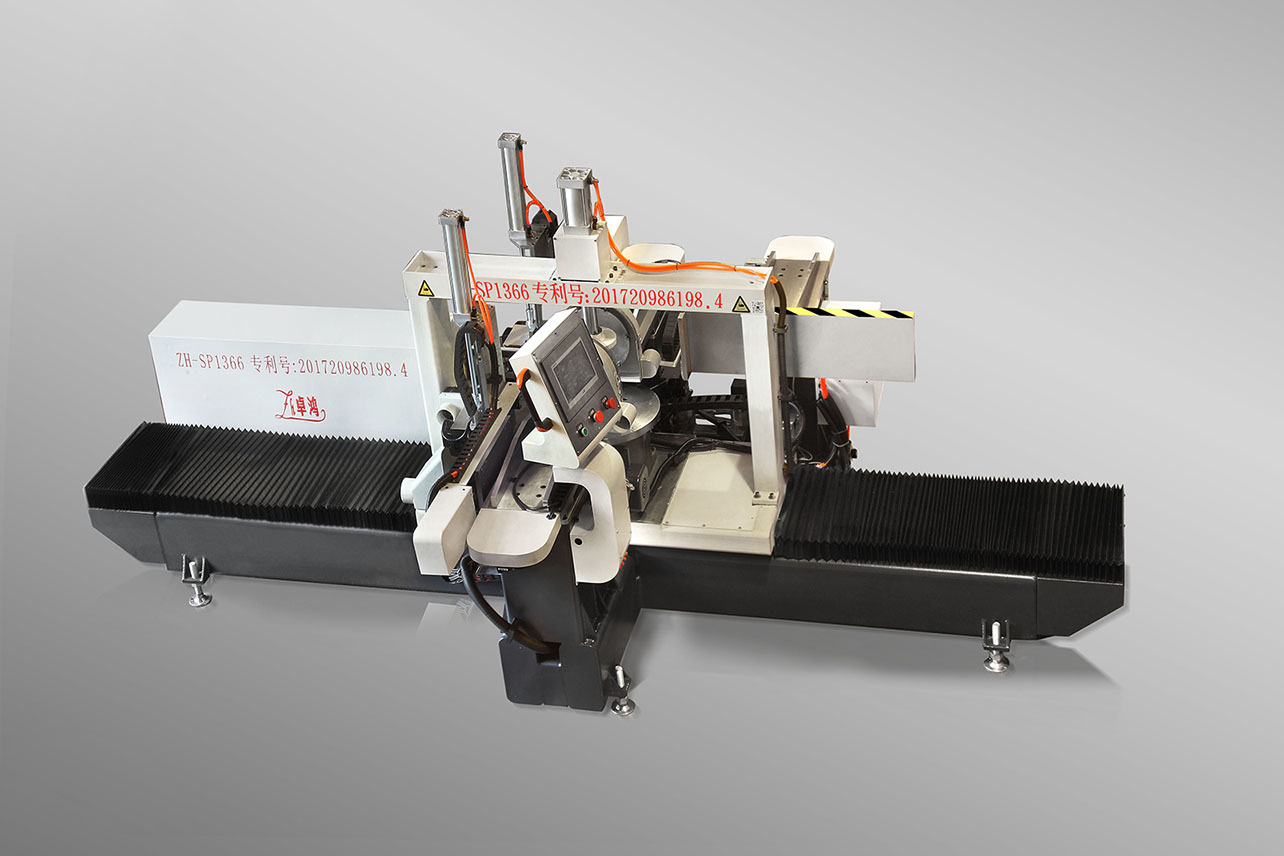

Features of electronic panel saws

By adding automatic feeding and positioning devices to the reciprocating saw, an electronic panel saw is created. Electronic panel saws use CNC program control. Workers input the required dimensions and quantity of materials on a touch screen or PC, start the machine, and the machine automatically feeds, positions, and cuts the materials. It features high cutting accuracy and efficiency, reduces worker workload, and is widely used in furniture factories, packaging factories, hardware factories, and appliance factories (lighting) for efficient processing of panels. Below, we introduce the features of electronic panel saws. Features of electronic panel saw cutting: 1, Automatic saw carriage