Active polishing machine scheduled maintenance routine

Automatic Polisher Scheduled Maintenance Procedure

To ensure the automatic polisher operates correctly, clean the machine after each day's use to maintain a well-ventilated and organized environment. Personnel responsible for the repair and maintenance of the automatic polisher must strictly and carefully follow the machine's operating instructions, develop plans, and record repair details.

After every 40 hours of operation, check the air filters installed under each polisher and turntable, and clean the shafts (do not use compressed air).

After two months or 300 hours of operation, manually lubricate the shafts supporting the liquid wax spray gun movement.

After three months or 500 hours of operation, lubricate the main shaft, bearings, and turntable locking bolts. Manually lubricate the gears and turntable bearings.

Every four months or 650 hours, according to the instructions, lubricate the sleeves of the transverse converter and the lubrication points of each polisher, and lubricate the ball bushings on the converter table and the ball bushings on the upper inclined table. Manually lubricate the rack and pinion.

Every six months or 1000 hours, turn off the power to the main control box, carefully clean the electrical box, use a vacuum cleaner to remove metal dust; check the function of the indicator lights and replace them if necessary; ensure that the moving compressed air pipes are not damaged and that the pressure gauge pressure adjustment works correctly; check that the electric motor bearings are noise-free and replace them if necessary; keep the exterior of the electric motor clean and away from polishing powder and grease; ensure that the motor ventilation is normal and unobstructed; check that the metal protective plates are in good condition.

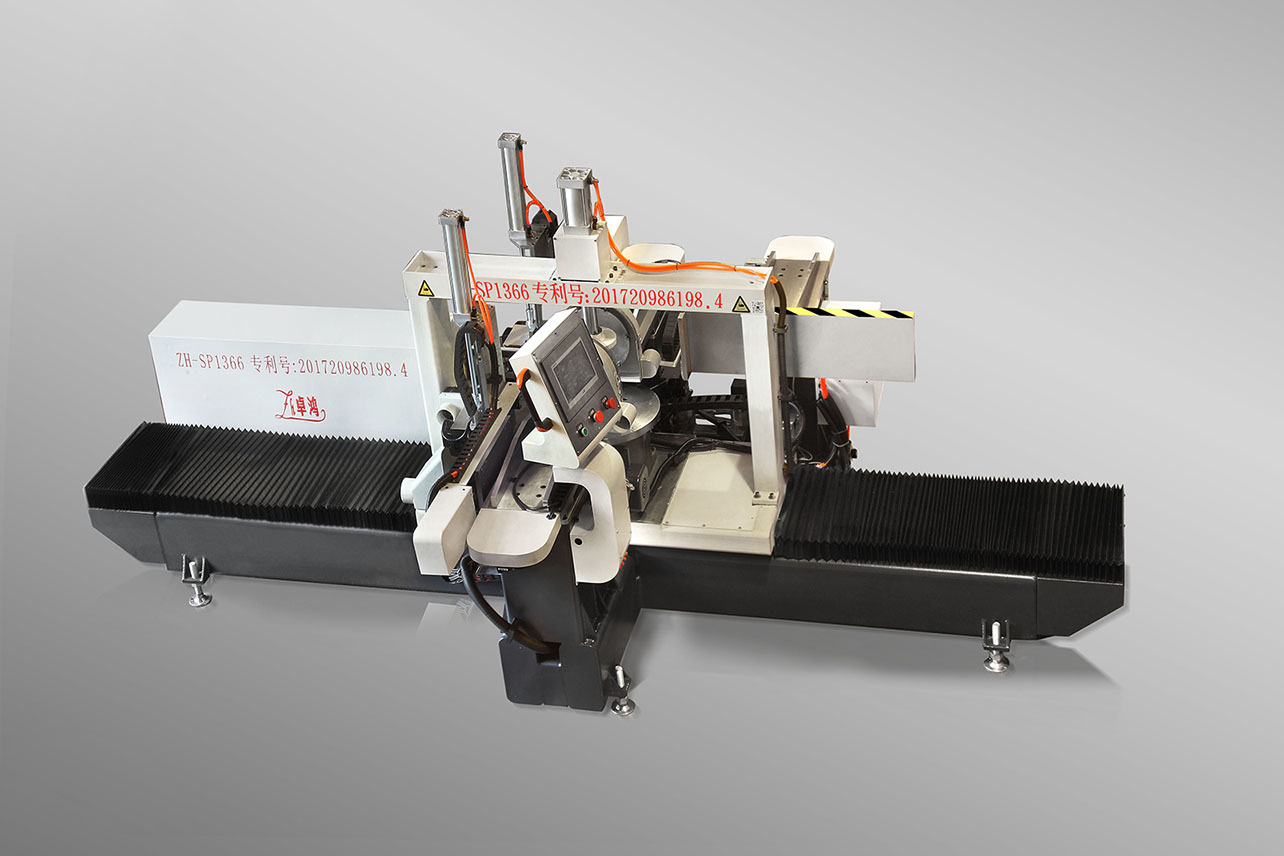

Acrylic Polisher

Related News

Features of electronic panel saws

By adding automatic feeding and positioning devices to the reciprocating saw, an electronic panel saw is created. Electronic panel saws use CNC program control. Workers input the required dimensions and quantity of materials on a touch screen or PC, start the machine, and the machine automatically feeds, positions, and cuts the materials. It features high cutting accuracy and efficiency, reduces worker workload, and is widely used in furniture factories, packaging factories, hardware factories, and appliance factories (lighting) for efficient processing of panels. Below, we introduce the features of electronic panel saws. Features of electronic panel saw cutting: 1, Automatic saw carriage