Professional light guide plate polishing machine manufacturer in Guangdong

Guangdong professional light guide plate polishing machine manufacturer

The ultimate goal of polishing and grinding polishing materials is to find ways to increase the polishing rate. At the same time, the polishing and grinding damage layer must not affect the finally observed microstructure. The former requires the use of coarser polishing materials for grinding abrasives, while the latter requires the use of the finest polishing materials for grinding.

What precautions should be taken for polishing and grinding polishing materials?

The ultimate goal of polishing and grinding polishing materials is to find ways to increase the polishing rate. At the same time, the polishing and grinding damage layer must not affect the finally observed microstructure. The former requires the use of coarser polishing materials for grinding abrasives, while the latter requires the use of the finest polishing materials for grinding materials. How should these two polishing material grinding problems be solved simultaneously?

When polishing and grinding workpieces with polishing materials, the specimen's ground surface and the polishing disc should be placed in a parallel position. At the same time, the specimen should rotate on its own and move back and forth along the radius of the grinding disc to avoid excessive local wear of the polishing cloth. During the polishing process, polishing liquid should be continuously added to keep the polishing material and polishing cloth at a certain humidity.

The speed of the polishing and grinding disc should preferably not exceed 500r/min; because the polishing and grinding time should be long, and the disc speed can be appropriately increased during fine polishing, the polishing and grinding time should be such as to remove the damage layer from coarse polishing.

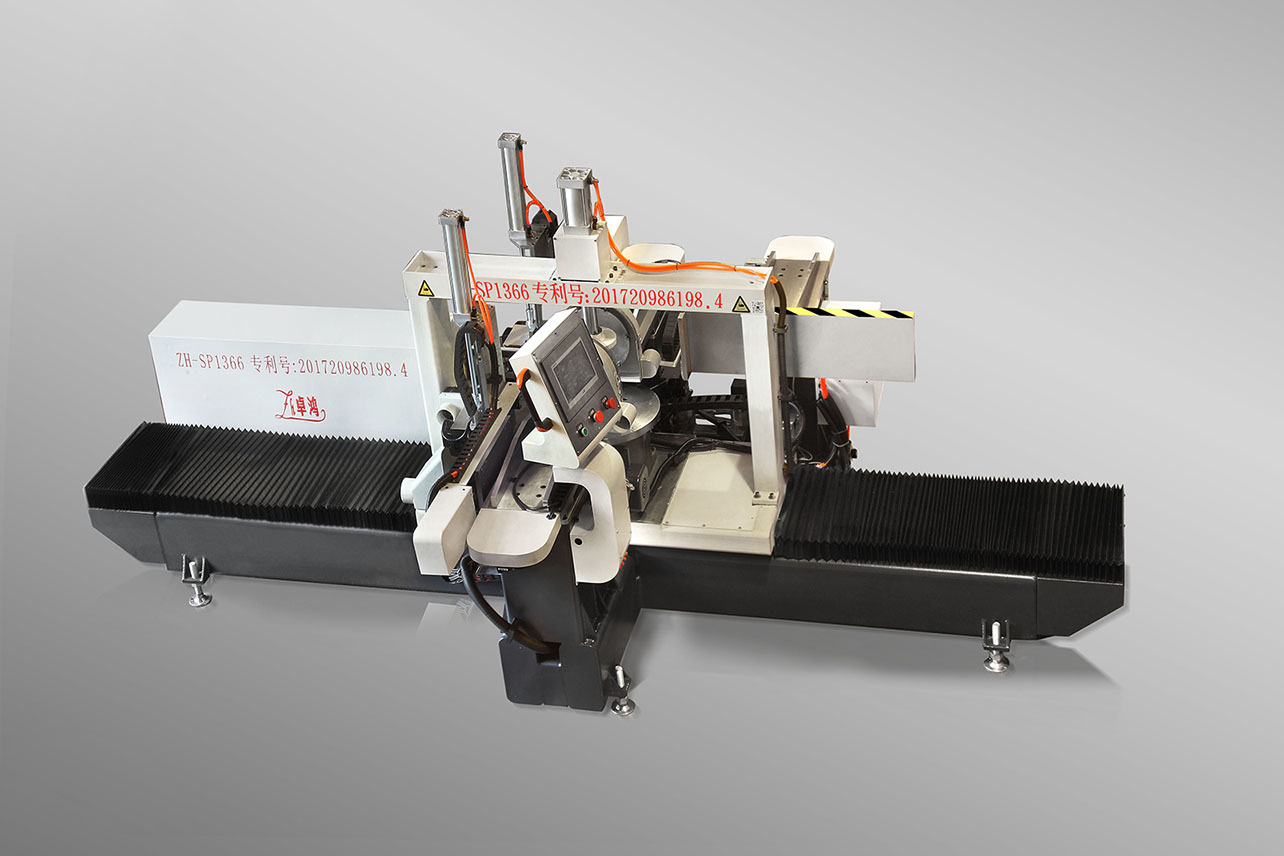

Foshan Zhuohong Electromechanical Equipment Co., Ltd. focuses on the R&D and production of light guide plate polishing machines.

Our company has strong strength and excellent light guide plate polishing machine production equipment. With rich experience in light guide plate polishing machine production and quality management, and an exquisite technical team, we will do our best to help customers solve various problems encountered in grinding and polishing, providing high-quality light guide plate polishing machine products and professional services to a wide range of new and old customers.

Foshan Zhuohong Electromechanical Equipment Co., Ltd.

Contact Person: Mr. Zheng (13923212848)

Tel: 0757-81180742

Fax: 0757-81180743

Email: zhuohong2011@126.com

Nationwide Free Service Hotline: 400-670-5068

Address: No. 65, Hengjiao Industrial Zone, Xiebian, Nanhai District, Foshan City

Related News

Features of electronic panel saws

By adding automatic feeding and positioning devices to the reciprocating saw, an electronic panel saw is created. Electronic panel saws use CNC program control. Workers input the required dimensions and quantity of materials on a touch screen or PC, start the machine, and the machine automatically feeds, positions, and cuts the materials. It features high cutting accuracy and efficiency, reduces worker workload, and is widely used in furniture factories, packaging factories, hardware factories, and appliance factories (lighting) for efficient processing of panels. Below, we introduce the features of electronic panel saws. Features of electronic panel saw cutting: 1, Automatic saw carriage