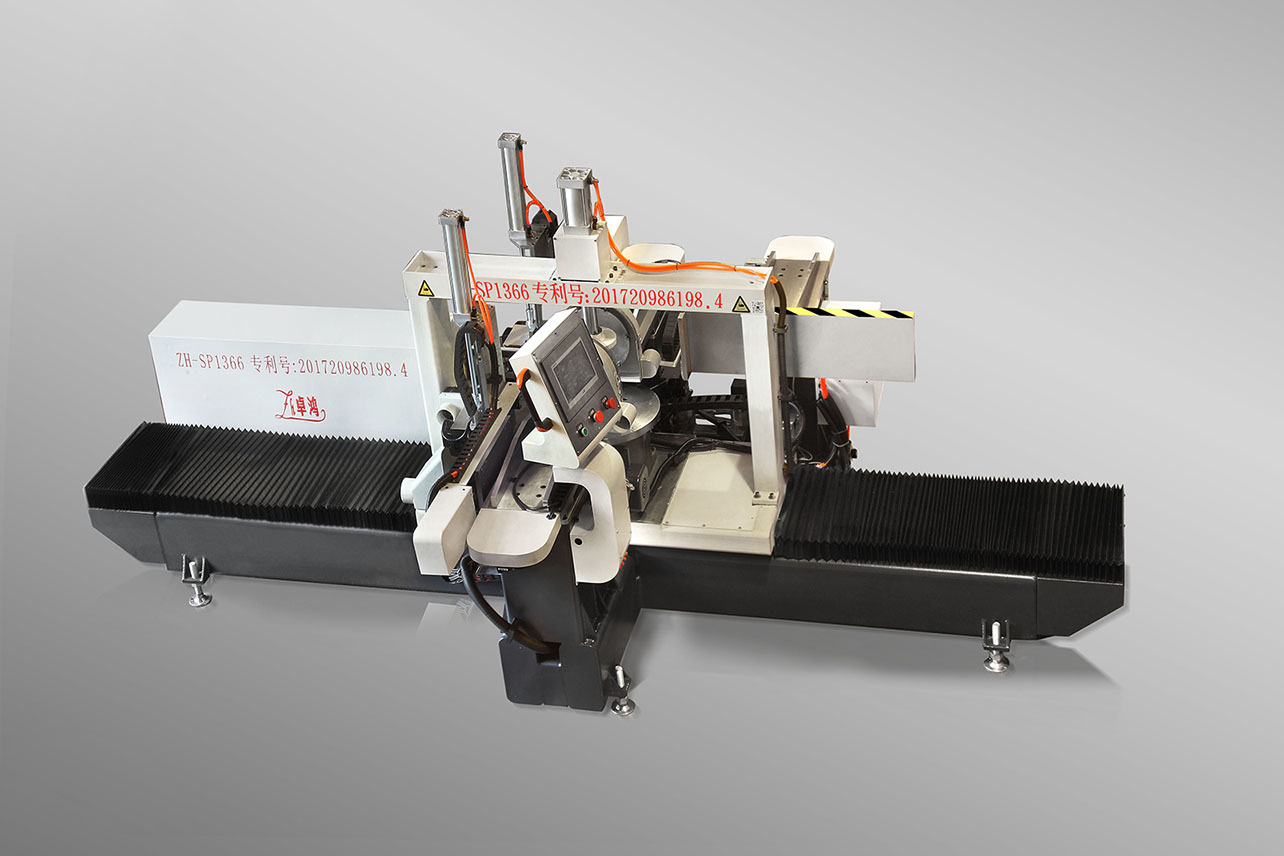

Main advantages of acrylic diamond polishing machine

Acrylic Diamond Polishing Machine Main Advantages:

1. Extremely high processing efficiency; one machine's daily output exceeds that of 30 workers.

2. High time utilization; after the worktable cutting process is completed, it can quickly return to its original position, saving 1/2 to 1/3 of the effective time.

3. Processing the joints of acrylic mirrors eliminates defects such as bubbles caused by traditional processes.

4. This polishing machine is widely applicable. It can process workpieces with larger or smaller widths, omitting traditional processing steps such as planing, polishing, grinding, and scraping, saving manufacturing costs and reducing the loss rate.

5. Using a diamond polishing machine improves processing accuracy. This machine uses a dial indicator to control the cutting depth, making it simple and easy to operate.

Diamond Polishing Machine It is an environmentally friendly product. Using a diamond polishing machine is dust-free and splash-free, avoiding the dust from traditional polishing machines and keeping the work environment clean.

7. The diamond polishing machine is highly safe to operate, avoiding accidents that can injure workers' fingers, eyes, etc., which can occur in traditional manufacturing processes.

8. Using this polishing machine eliminates the need for additional dust prevention equipment. The cutting tools are reliable, have a long service life, and provide stable processing quality and dimensions. It has a small footprint and significantly reduces the manufacturing cost of acrylic products.

To learn more about Acrylic Polishing Machine, Acrylic Double Polishing Machine, Acrylic Diamond Polishing Machine For more information, please visit the Foshan Zhuohong Electromechanical Equipment Co., Ltd. website http://www.fszhjd.com

Related News

Features of electronic panel saws

By adding automatic feeding and positioning devices to the reciprocating saw, an electronic panel saw is created. Electronic panel saws use CNC program control. Workers input the required dimensions and quantity of materials on a touch screen or PC, start the machine, and the machine automatically feeds, positions, and cuts the materials. It features high cutting accuracy and efficiency, reduces worker workload, and is widely used in furniture factories, packaging factories, hardware factories, and appliance factories (lighting) for efficient processing of panels. Below, we introduce the features of electronic panel saws. Features of electronic panel saw cutting: 1, Automatic saw carriage