Recommended Products

ZH-WS1650X1

ZH-WS1650X1

Recommended Products

ZH-YJ100

ZH-YJ100

Recommended Products

ZH-PMMA1326

ZH-PMMA1326

Recommended Products

ZH-S5

ZH-S5

Recommended Products

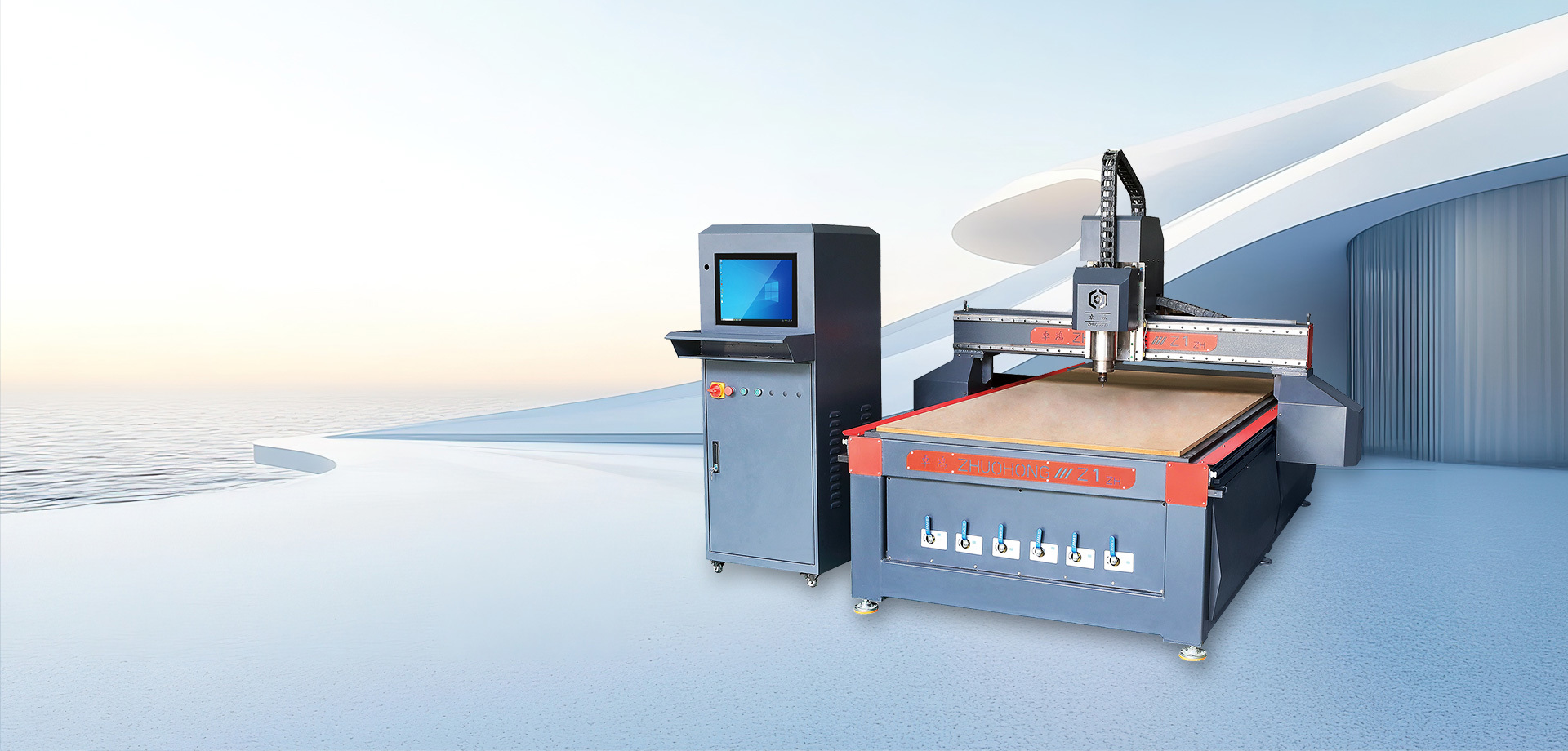

Z1-1325

Z1-1325

Advantage

Zhuohong Machinery3Major Advantages

Strong technical force

Let quality speak for the product

High-quality products, high-quality service, customer first

About Us

Professional acrylic/light guide plate/digital board saw equipment manufacturer

Foshan Zhuohong Electromechanical Equipment Co., Ltd. is a professional manufacturer specializing in the production of acrylic diamond polishing machines, laser machines, engraving machines, and electronic cutting saws. We provide R&D, manufacturing, sales, and technical support.

Our company has strong technical strength. The R&D center brings together senior and intermediate R&D engineers from the machinery and non-standard equipment industries. The company is committed to the R&D, production, and sales of high-tech polishing machines. "Dare to struggle, strive for innovation" is the belief of the Zhuohong team. Our company adheres to the tenet of "high-quality products, high-quality service, customer first" to provide customers with high-quality products, reasonable price-performance ratio, and fast delivery time. With enthusiastic and thoughtful service, we provide customers with high-quality and economical and durable products.

Company Establishment Date

Professional technicians

Invention patents, utility model patents

Export to more than 50 countries and regions

Honors

Honors and Qualifications

NEWS

Blog

2024-12-27

Features of electronic panel saws

2024-12-27

2024-12-27

Certification

Up to now, the company has applied for more than 100 patents, including invention patents and utility model patents.

Online Message

Please leave your contact information, we will contact you as soon as possible after receiving it, and we will serve you wholeheartedly!