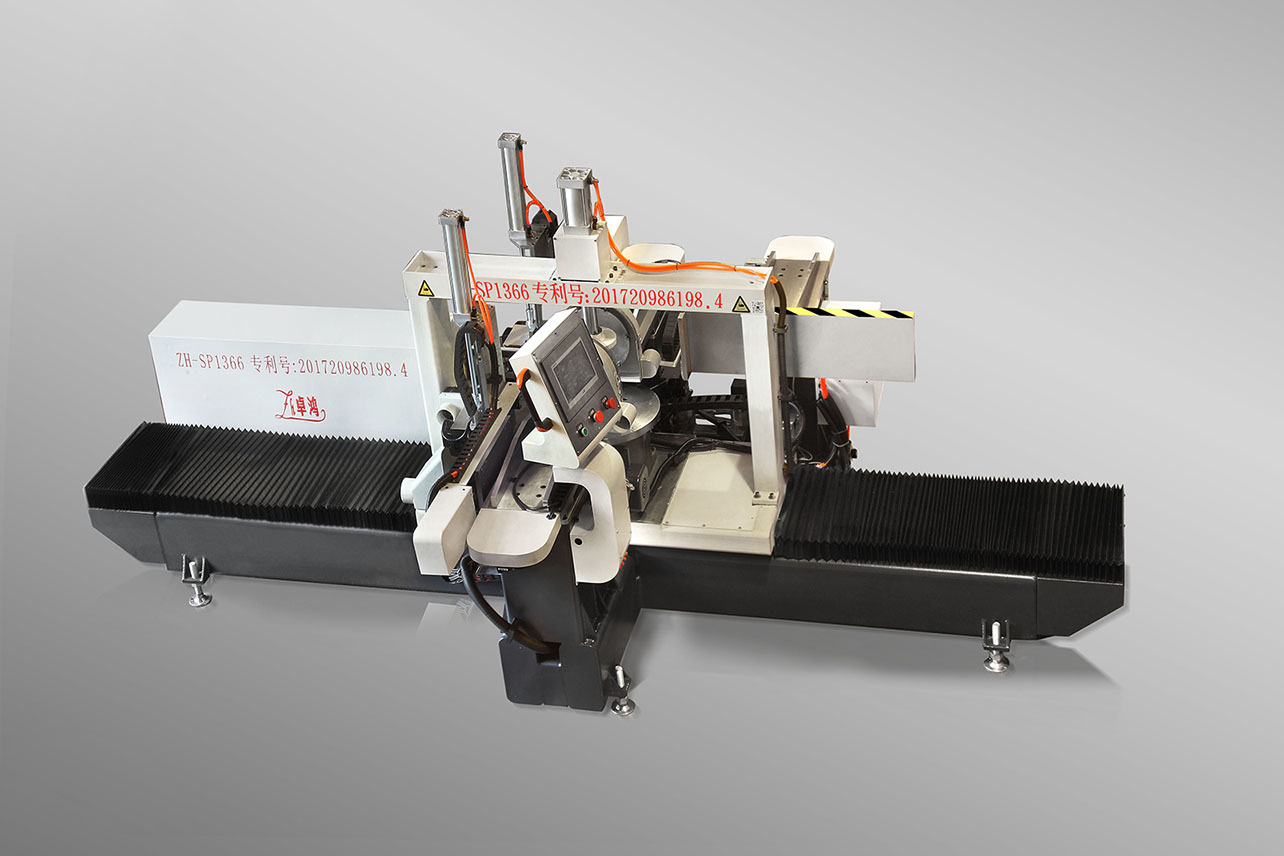

The most cost-effective acrylic diamond polishing machine manufacturer

The most cost-effective acrylic diamond polishing machine manufacturer

Foshan Zhuohong Electromechanical Equipment Co., Ltd., specializing in the production of acrylic diamond polishing machines.

If acrylic diamond polishing machines are well maintained, their service life can be extended. Below, we introduce how to maintain and care for acrylic diamond polishing machine products.

1. Cleaning: Acrylic diamond polishing machine products, if not specially treated or added with hardening agents, are prone to wear and scratches. For general dust, use a soft cloth or rinse with clean water. Then wipe with a soft cloth. If there is oil on the surface, use a mild detergent with water and wipe with a soft cloth.

2. Waxing: To make acrylic diamond polishing machine products shiny and bright, you can use liquid polishing wax and wipe evenly with a soft cloth.

3. Adhesion: If acrylic diamond polishing machine products are accidentally damaged, they can be bonded with dichloromethane-based adhesives or quick-drying agents.

4. Polishing: If acrylic diamond polishing machine products are scratched or the surface wear is not very serious, you can try using a polishing machine with a cloth wheel, applying an appropriate amount of liquid polishing wax, and polishing evenly to improve.

To learn more about "acrylic diamond polishing machines," please feel free to call us for a discussion!

Foshan Zhuohong Electromechanical Equipment Co., Ltd.

Contact Person: Mr. Zheng (13923212848)

Phone: 0757-81180742

Fax: 0757-81180743

Email: zhuohong2011@126.com

National Free Service Hotline: 400-670-5068

Address: No. 65, Hengjiao Industrial Zone, Xiebian, Nanhai District, Foshan City.

Related News

Features of electronic panel saws

By adding automatic feeding and positioning devices to the reciprocating saw, an electronic panel saw is created. Electronic panel saws use CNC program control. Workers input the required dimensions and quantity of materials on a touch screen or PC, start the machine, and the machine automatically feeds, positions, and cuts the materials. It features high cutting accuracy and efficiency, reduces worker workload, and is widely used in furniture factories, packaging factories, hardware factories, and appliance factories (lighting) for efficient processing of panels. Below, we introduce the features of electronic panel saws. Features of electronic panel saw cutting: 1, Automatic saw carriage